No matter what is used, it will cause wear, but the degree of wear is different.

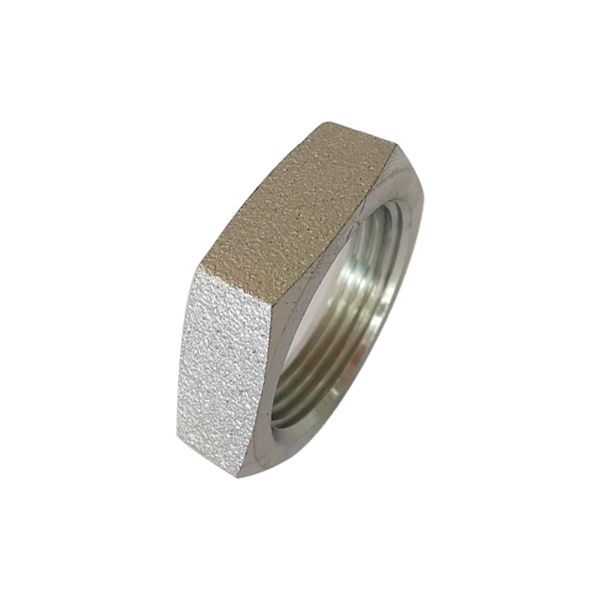

Take the hydraulic accessories, for example, there are many types of hydraulic accessories, and wear will inevitably occur in the hydraulic device. At this time, we should pay attention to their maintenance problems, otherwise the time will seriously affect the use of equipment, and we need to do Good regular inspection work. Let's take a look at the reasons why hydraulic accessories wear, so that you can better use hydraulic accessories and maintain it in time.

Causes of wear on hydraulic accessories

1. First of all, the use of hydraulic accessories should be reasonable. At the same time, we must pay attention to quality problems when buying. Otherwise, if the quality of the accessories is not good, it will cause serious wear and even damage to the accessories in the short term, so the quality of the product We must pay attention to it.

2. We must pay attention to the use of hydraulic accessories, and the types of accessories are somewhat different, so we have to use them correspondingly, and it is necessary to select the appropriate accessories to ensure long-term use, and it is necessary to replace them if they are seriously worn.

The automatic magnetic deburring and polishing machine bai mainly polishes precision parts such as turning processing, stamping, die-casting, CNC, machining, etc., removing burrs, chamfering, polishing, cleaning and other precision grinding work at one time. It only takes 3-15 minutes to complete! Does not damage the precision of the workpiece! Irregular parts, inside holes, inside pipes, dead corners, gaps, etc. can all be ground.

Suzhou Aochen deburring magnetic polishing machine, magnetic grinding machine, magnetic deburring, (zinc, aluminum, copper, titanium, stainless steel) precision small parts inner hole, gap, dead corner grinding, polishing, cleaning, deburring, etc.

Equipment introduction:

Magnetic polishing machine-uses the power of a magnetic field to guide the abrasive material (magnetic needle) to quickly rotate and grind the workpiece to achieve high-efficiency deburring (batch front), surface polishing, brightening, cleaning, oxide film removal, sintering marks, Grinding effect such as rust removal.

●The surface of the workpiece is polished, polished and smooth

●Deburring, burrs, burrs, burrs

●To remove the oxide film

●Remove traces of sintering and restore the original color of metal

●Clean and remove metal processing chips and slag

●Swivel and rounded edges

●Optimize surface plating and electric welding

●Removal of paint on metal surface

More about:stainless steel fittings factory

Megosztás a facebookon